Museums guard history, culture, and art, play a crucial role in preserving valuable artifacts and…

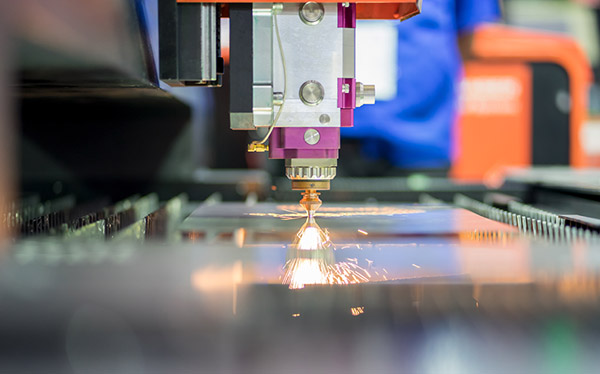

When it comes to custom metal decals, labels, tags, and nameplates in Canada, Identifab Industries is the place to go. Identifab Industries is a leading metal tags manufacturer, producing high-quality custom metal products that exceed your expectations.

Finding a reliable provider for your custom metal needs is essential. As an industry leader since 1969, Identifab Industries is a trusted name among metal tags manufacturers.

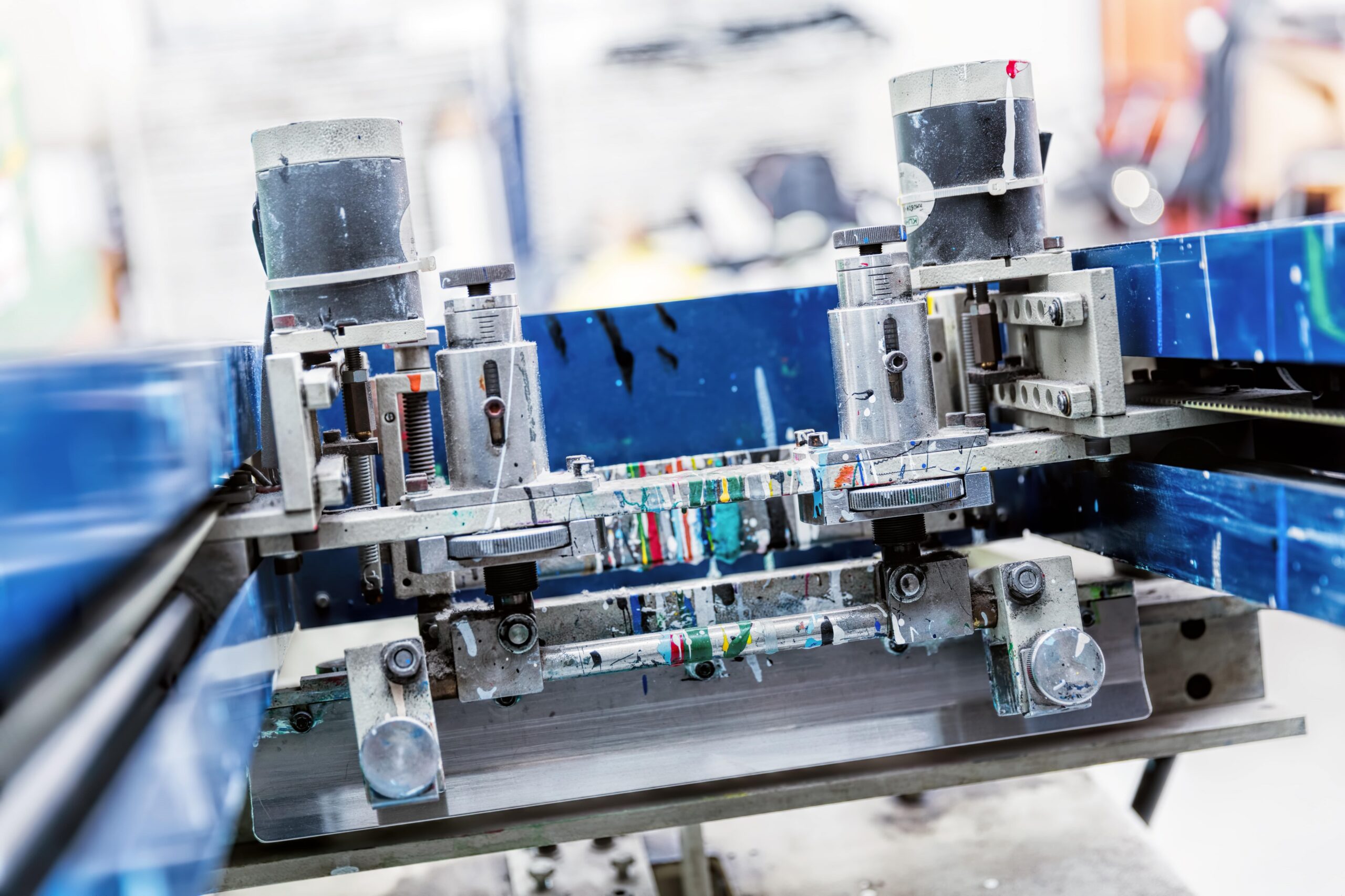

Whether you need only a handful of tags or a thousand labels, decals, or nameplates, we can help. We use the latest technology and equipment to produce high-quality custom metal products. Partner with our skilled and helpful staff, and you have a winning team. Contact us today to learn more about our services or to request a quote.

VIEW MORE

We have been doing business with Identifab Industries Limited for close to 10 years and will continue to work with Identifab for many years to come. The quality of work and service has impressed me on a multitude of levels.They are efficient and are always able to deliver a quality product in a timely manner, not to mention the friendliness, professionalism, great customer service and family oriented atmosphere.

Thank you Identifab family for your superior service over the years.

As a longtime supporter of Trench Ltd (since 1970), we have found Identifab to be a very valuable supplier. We have had continued success with this relationship over the years due to their quality of product, customer service, on time delivery and especially their ability to regroup during our unusual trending of ups and downs in Production requirements. They pull out all the stops to make these trends flow as smoothly as possible. I would recommend this supplier without hesitation.